- Accueil >

- Security and Safety Insights >

- Misconceptions About Isolation Point Naming Conventions

Misconceptions About Isolation Point Naming Conventions

Following OSHA regulations can be tricky if you’re not clear on what the standard actually is. Too often, we see good intentions and misinterpretation of the OSHA 1910.147 regulation. This article looks to provide a solution to a common misconception about the required naming conventions for identifying energy isolation points.

Preventing Confusion When Identifying Energy Isolation Points

OSHA requires that the written lockout procedure identify the energy isolation points that need to be locked out that achieve a zero-energy state. This requires recognition of hazardous energy – which includes, but not limited to: electrical, pneumatic, hydraulic, gravity, water, chemical, or other hazardous energies. Once these isolation points are identified, a naming convention needs to be allocated and the isolation points tagged so the written procedure can accurately describe the lockout process and the authorized person can be assured the correct points have been identified.

Typically, we see companies employing a methodology of using E1 for the first electrical isolation point for a machine, P1 for the first pneumatic isolation point, W1 for the first infeed or outfeed of a water isolation point, and so on. The problem arises when this same naming methodology is used for all machines – so machinery within your facility will have the same isolation point naming conventions - multiple isolation points that are both named E1 or W1.

While there isn’t necessarily a violation of OSHA standards in naming isolation points like this, there is a high probability of confusion. Depending on your facility layout, you could have multiple isolation points located close together and labeled and named the same. If an authorized employee was trying to follow the written procedure, there is a strong possibility that they may not know where to apply their lockout equipment with multiple E1’s or W1’s tagged in an immediate area.

NFPA 70E and electrical isolation points

An actual violation can occur if your facility uses this methodology for electrical lockout. Per NFPA 70E®, all electrical devices need to have unique names. So, if your facility has multiple electrical isolation points labeled “E1,”and no other naming convention to the electrical devices your facility may be outside the bounds on the NFPA 70E standard.

Bringing clarity to naming conventions

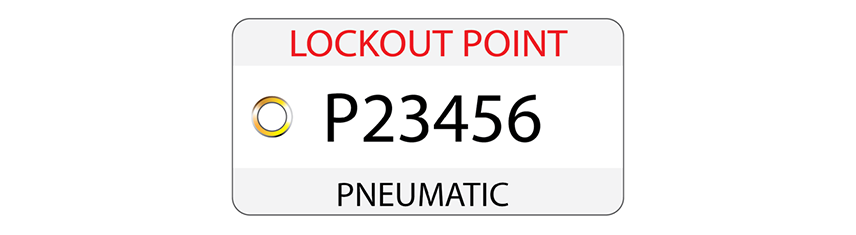

Master Lock recommends specifically identifying each energy isolation point with its own serialized name. This will ensure your electrical isolation points keep a facility within bound of NFPA 70E, it also helps clarify all written lockout procedures for the entire facility. For example, if you have multiple machines that all have pneumatic isolation points, you may name and tag that P-01234, and then the next machine with pneumatic will be labeled and tagged P-01235, and so on. This is then noted on the written procedure that identifies the exact lockout point in the facility that needs to be locked out.

A variety of different type of étiquettes

Isolation points need to be clearly marked within your facility. If you work in an environment that is relatively clean, plastic isolation points will work great. If you have a hot environment, or an environment that is exposed to the elements, metal or brass tags will hold up better than a standard plastic tag. However, in the food processing industry, foreign materials such as plastic, cannot be close to the manufacturing process and is something that needs to be strictly enforced. To avoid foreign materials within this process, metal detectable tags, brass, or stainless-steel isolation point tags will be required. This type of material for isolation point tags may also need to stand up to frequent sanitation processes or persist in extreme environments. While these guidelines are not specified within OSHA guidelines, they may be required by other government safety standards.

If you’re interested in working with Master Lock to create a comprehensive lockout program, get in touch with one of our experts today.

NFPA 70E® is a registered trademark of National Fire Protection Association, Quincy, MA